Get a Quote

Fill out the form below for Availability & pricing

close

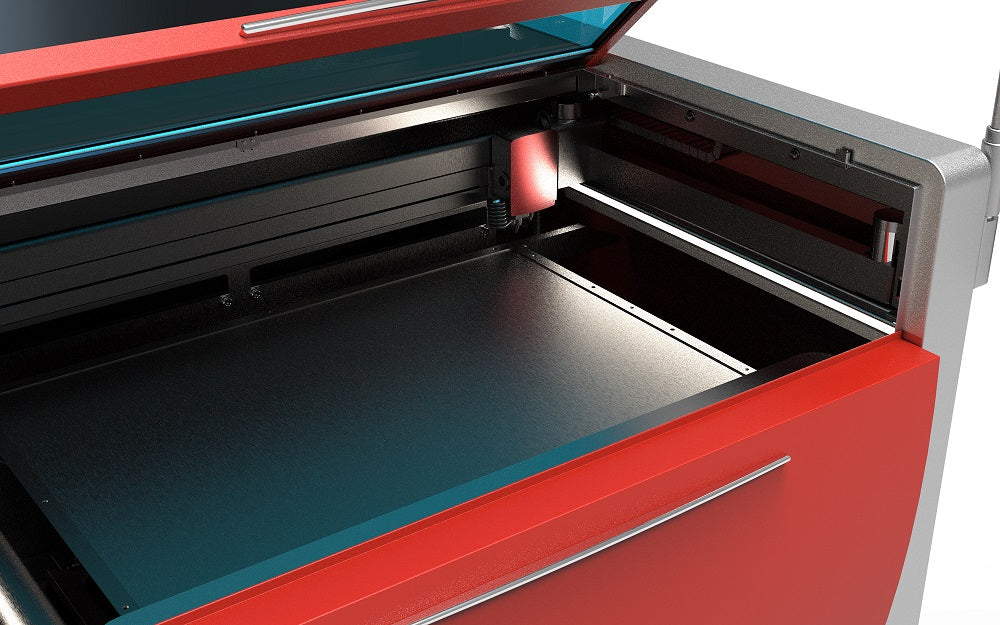

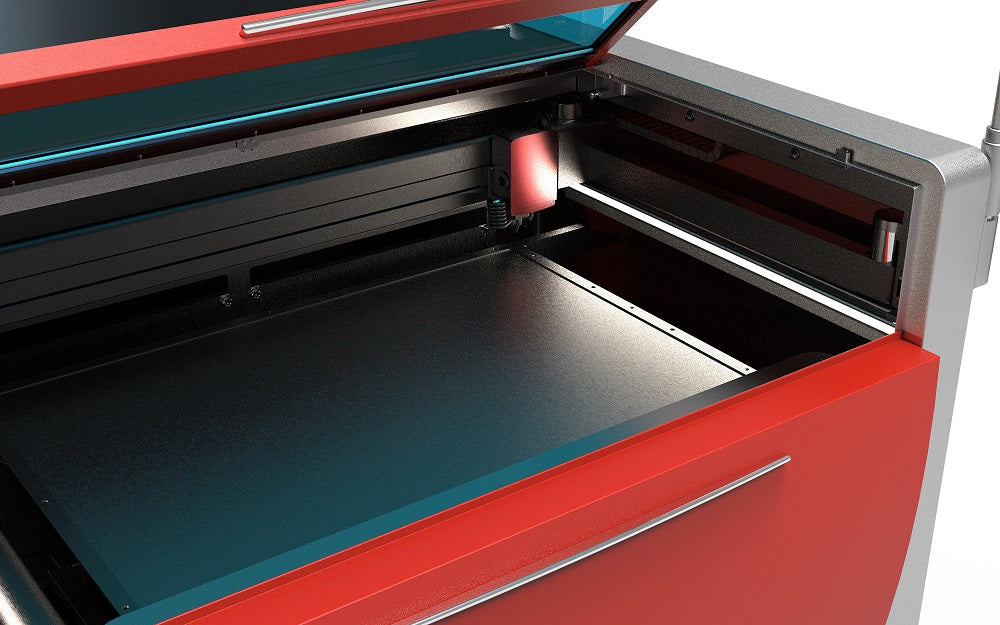

The ULTRA X6000 stands out as a high-precision laser material processing system, tailored for the demanding and intricate requirements of manufacturing, prototyping, and research and development environments. This system sets a new benchmark in accuracy, repeatability, and efficiency, surpassing traditional methods and offering a suite of advanced features and capabilities. It's designed to deliver impeccable quality across a diverse range of materials, addressing virtually any material challenge in a single system.

Ultimate Material Processing Flexibility

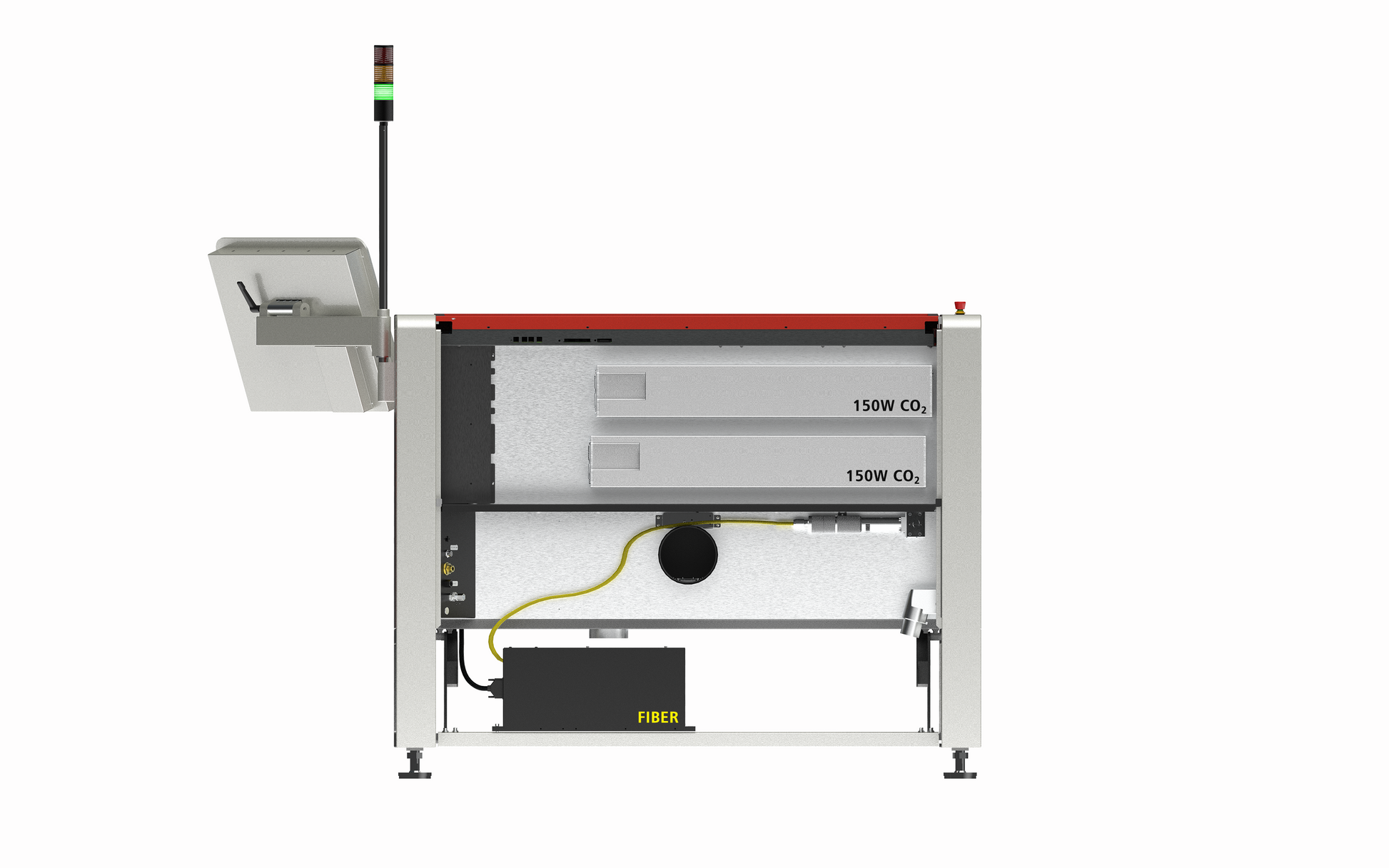

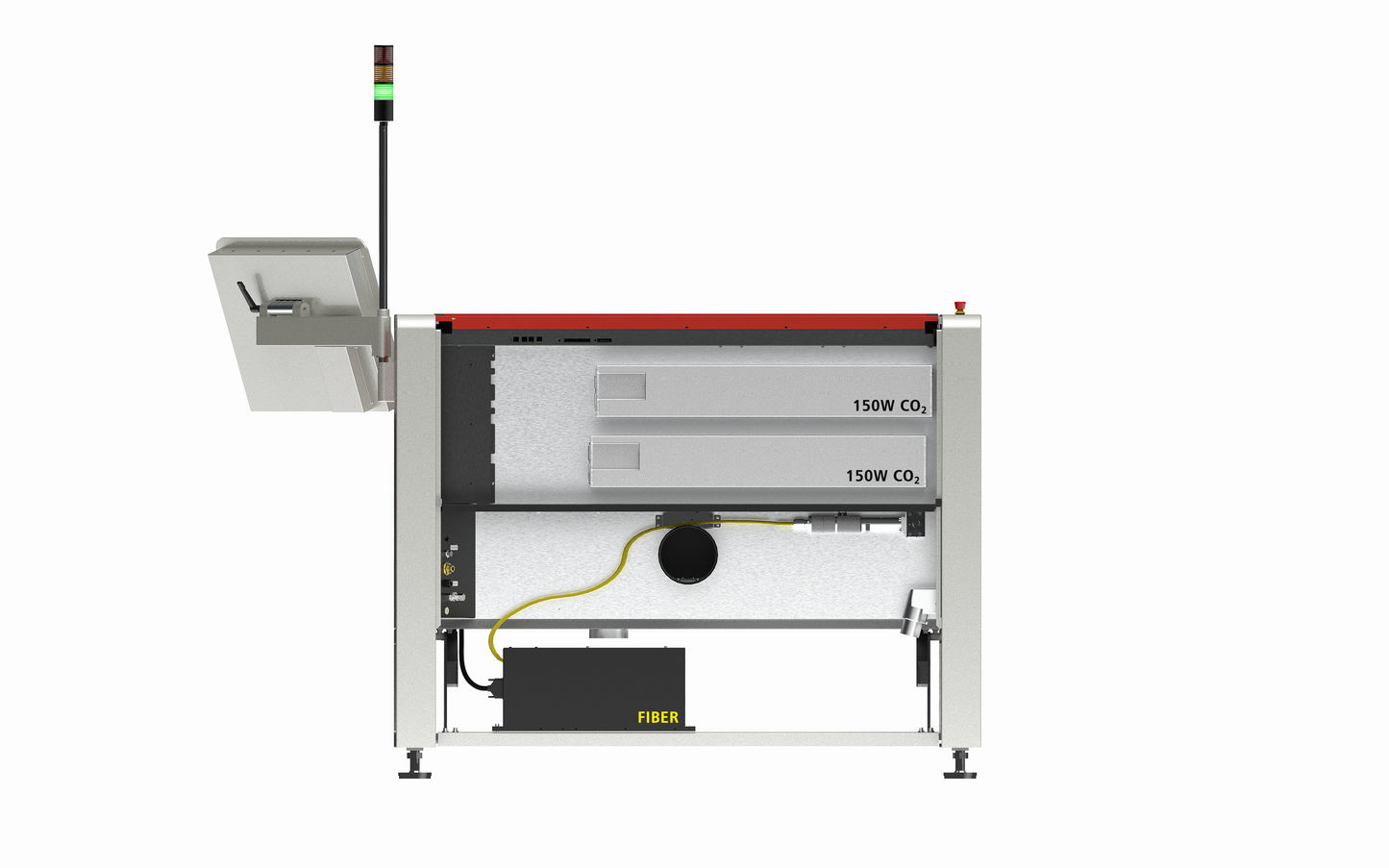

- Multi-Wave Hybrid™ Technology: The ULTRA X6000 supports three laser wavelengths (10.6, 9.3, and 1.06 µm) and offers laser power ranging from 10 to 300 watts CO2 and 50 watts fiber. Its patented Multi-Wave Hybrid™ technology allows the combination of multiple laser beams of various wavelengths and power into a single coaxial hybrid beam.

Key Features and Capabilities

- Material Processing Area: 36 x 24 inches (914 mm x 610 mm), accommodating material thickness up to 12 inches (305 mm).

- Laser Sources: Supports up to two CO2 laser sources and one fiber laser.

- Advanced Optics: Includes camera registration, automation interface, and patent-pending Controllable Power Density Optics.

- Precision and Control: Features precision material-independent autofocus, programmable gas assist, and the Laser System Manager control software.

- User Interface: Equipped with a 21-inch (533 mm) touch screen control panel.

- Rapid Reconfiguration™ Technology: Ensures quick adaptability to varying processing requirements.

Performance Specifications

- Processing Speed: Maximum positioning speed of 175 in./sec (4445 mm/sec), with effective raster processing and functional vector processing speeds exceeding 300 in./sec (7620 mm/sec) in SuperSpeed configuration.

- Repeatability and Precision: Mechanical positioning repeatability is ± 10 microns, with 2-micron beam position addressability.

- System Dimensions: Width ranges from 63.09 inches (1603 mm) with the control panel folded to 87.75 inches (2229 mm) extended. The depth is 50.07 inches (1272 mm), and the height reaches up to 74.42 inches (1890mm) at the top of the light tower.

- Weight and Power Requirements: The system weighs 550 lbs. (250 Kg) and requires a power supply of 220V-240V/20A.

Safety and Compliance

- Laser Safety Classification: Classified as Class 1 for material processing lasers and Class 2 overall, with an option to convert to Class 4.

- Exhaust Requirements: Intelligent Air Filtration (UAC 4000) or external exhaust blower capable of >700 CFM at 6 inches.

About Universal Laser Systems Inc. (ULS)

ULS, the manufacturer of the ULTRA X6000, is a renowned global entity based in Scottsdale, Arizona, with over 35 years of pioneering advanced laser equipment. The company's commitment to excellence aids organizations in solving complex material processing challenges, enhancing their capabilities, and improving existing material processing methods.

How to Order

We prefer online orders, but if you need to place an order using a purchase order or an alternate payment method, please fill out our request for quote form.

- Choosing a selection results in a full page refresh.

- Opens in a new window.