Improper Universal Laser operation often happens when a business has employee turnover or when a machine has multiple users and these new users haven’t received the same laser training that the business received with the machine installation. Of the most common user errors, laser focus is by far the most common laser operator error we see.

WHAT IS LASER FOCUS?

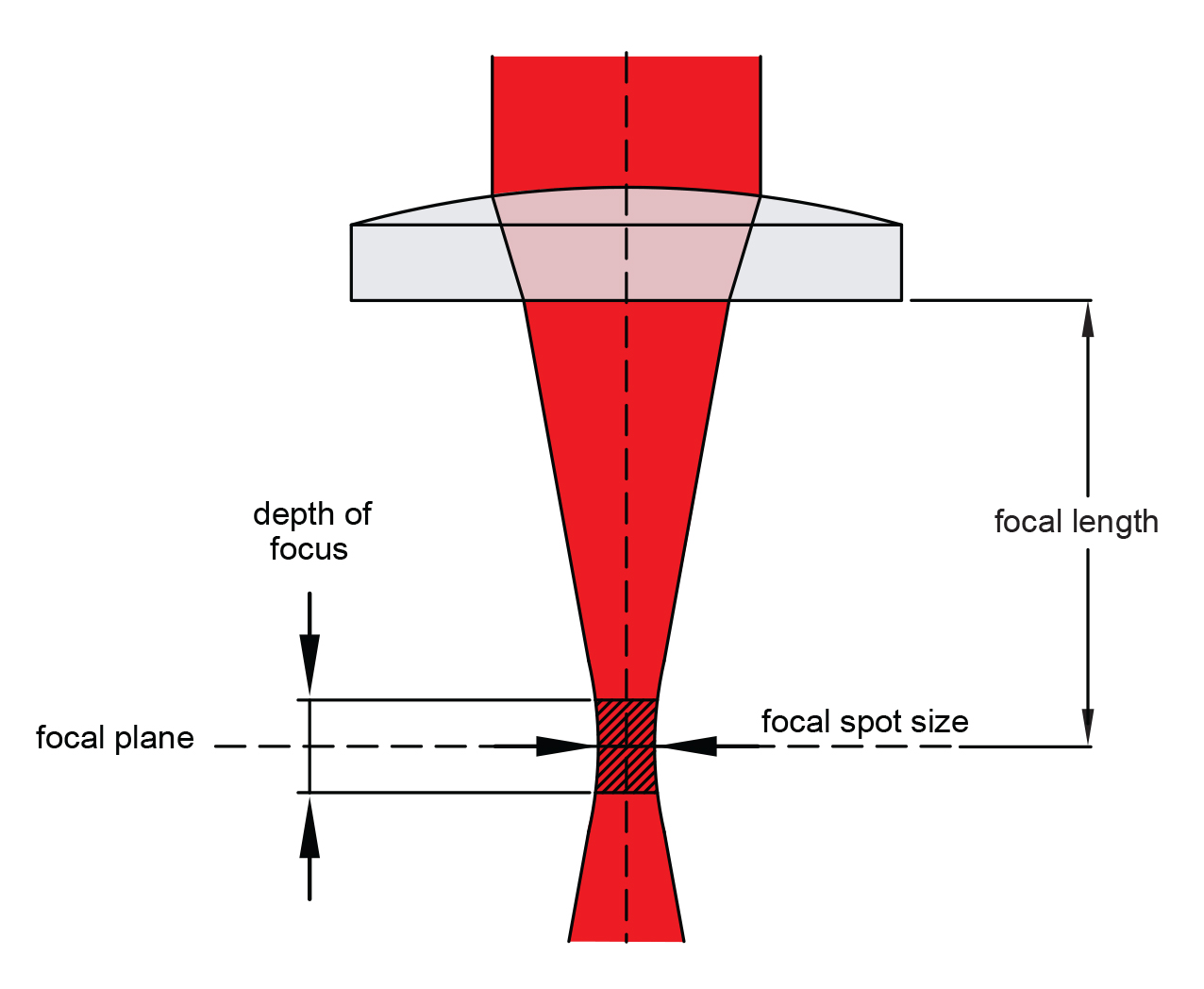

The term focus refers to the location in the path of the laser beam, after it passes through a focusing lens, where the laser light is concentrated into the smallest spot size and has the most laser power density. Another way of describing focus is the distance of your material from the laser lens where the laser gives the best resolution for engraving and where the laser has the sharpest point for cutting. If your target material is too far outside of the focal plane, your laser processing will result in poor laser engraving resolution and poor laser cutting ability.

The image above shows how the focusing lens narrows the laser light to a smaller diameter then spreads out again, forming an hourglass-like shape. The goal with laser focus is to have your material in the path of the laser beam where the spot size has the smallest diameter.

HOW TO FOCUS YOUR UNIVERSAL LASER

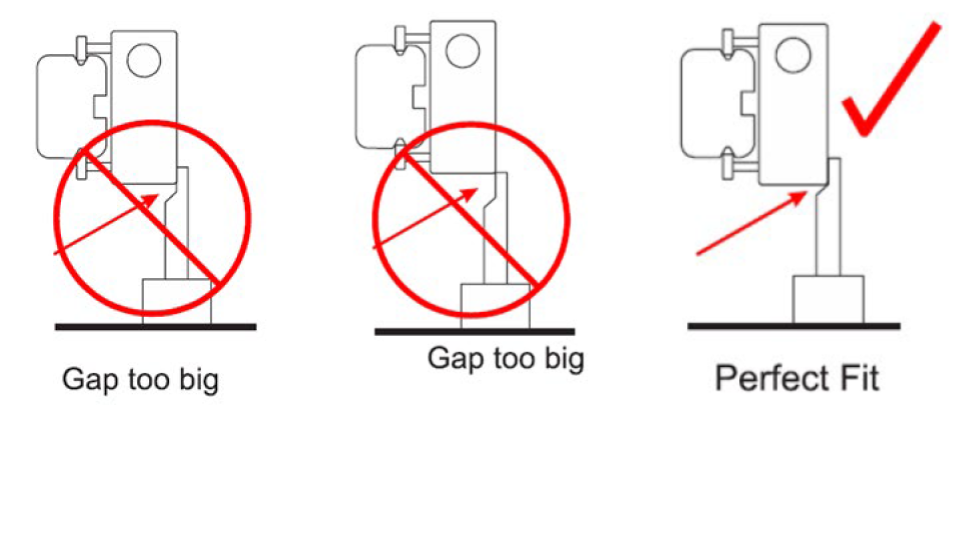

Unless you are using one of the new ULTRA laser models from Universal Laser Systems with Precision Material Independent Autofocus, the best way to know that your material is in the focal plane is to manually focus using the focus tool provided with your laser.

Pro tip: if you prefer to manually focus your laser, go into the Universal Laser Control Panel Software, click the system tab, and make sure the Autofocus feature is not selected. The autofocus will override your manual focus after start your job.

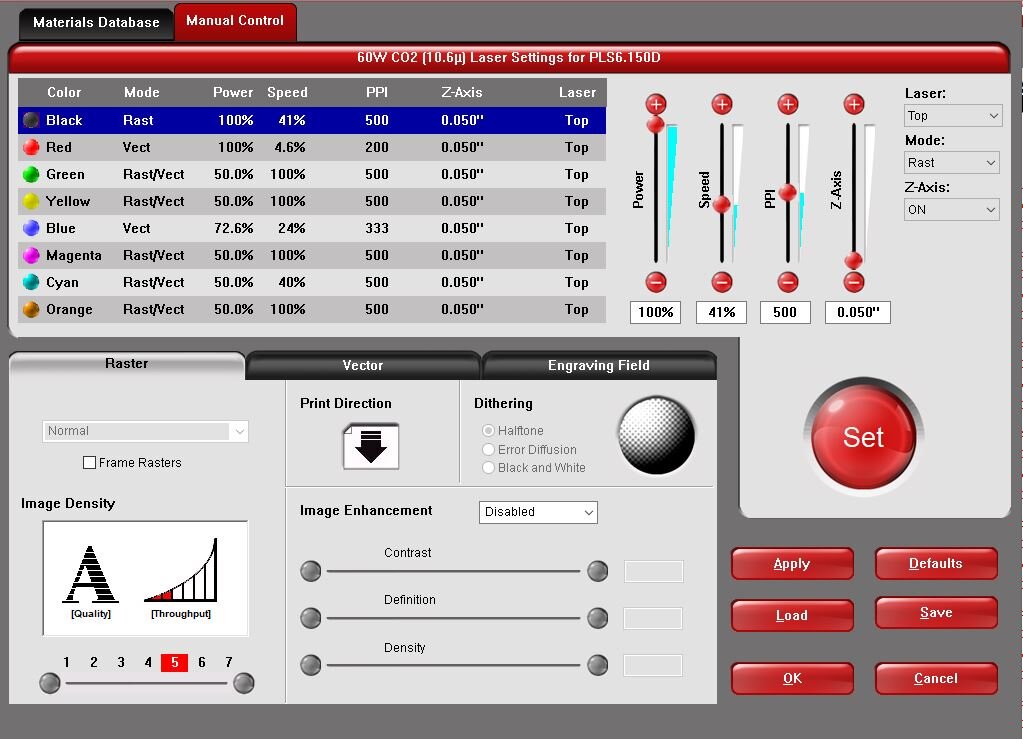

The other option for laser focus with Universal Laser systems is to use the Intelligent Materials Database or the Manual Control Settings and type in the thickness of your material. In the manual control, the Z-Axis setting refers to the material thickness. After the material thickness has been entered, the laser will automatically move the Z-axis and position your material in the focal plane at the beginning of the job file.

Just remember, the autofocus feature will always override your manual focus if you have it turned on in the system tab of the UCP.